Why the ADV1 Frame is Bolted, Not Welded

I worked at an aluminum bicycle company (Cannondale) in the mid-to late 80s. I started out in R&D then got promoted into purchasing. I was responsible for buying everything that was on Cannondale frames: all the aluminum tubing, the aluminum extrusions, stickers, injection molded cable guides, and more. I absolutely loved that job. I got to travel and see aluminum factories, injection molding factories, and most importantly, the Cannondale factory. I learned an enormous amount about aluminum tubing, welding it, and heat treating it.

So, with this background, when thinking about making the trailer I wanted for my wife and I to travel with, I immediately thought welded aluminum tubes was the right answer.

When we built our first prototypes of our single-wheel adventure moto trailer, we didn’t think of anything but a welded aluminum frame. And the first prototypes were amazing, but making them and then testing them pointed out a few problems with construction. It started with our fabrication partner: Alex at Alloy Specialties, Inc. Alex pulled us aside right after we pulled our trailer for the very first time. He said that the trailer was amazing, but we had to know welding wasn’t going to be an option for production. He walked us over to another building and showed us his very large CNC router.

A CNC router cutting out a part (not of the ADV1)

New Vision for the ADV1’s Design and Construction

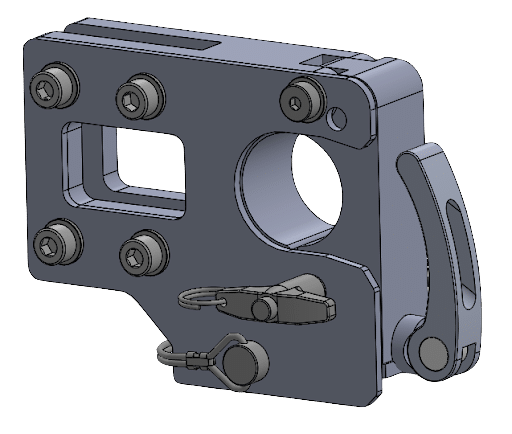

His vision for our trailer (now an award-winning moto trailer) was we would cut out a two large side frame pieces, then make our internal storage a load-bearing part of the frame. The suspension system would provide additional cross pieces, and we’d need to make a few cross pieces for a few spots other equipment wasn’t bridging the space between the two side frames.

It took me a day or two to get my brain around this idea. I had a long history with welded tubing, so I was pretty married to that idea. But once his thoughts finally took hold, I knew we were headed in an exciting, new, and better direction. We redesigned in SolidWorks CAD from nearly zero, and sent Alex the drawing for him to put into his router. Here’s the first picture he sent us of the two side frame pieces.

Now that we’ve built a prototype with those sides, have seen the process of making all the other parts, assembled the trailer, and tested it, we know we have made the right decision. Here’s what it looks like:

Eight Reasons the ADV1 Frame is Bolted, Not Welded

Cost – Our first prototypes made with welded aluminum tubing were insanely expensive. The tubes had to be cut by a 6-axis laser tube cutter in order for them to fit well enough together for even a master welder to be able to weld them. It cost $10k to cut enough tubes for two prototypes! Then we had to have complicated, expensive jigs made to hold the tubes so they could be welded straight and properly. Then we had to have a master welder do the welding, which is also is very expensive. All of this was very expensive.

Assembly Skill Levels – Welding is not a simple way of making a product. It takes very skilled people to do the work. Bolting a product together is a far simpler process; the people doing the work don’t need to be super skilled. The jobs are open to more people, and they will be able to do a superlative job without years of training to achieve the skill level we would require.

Assembly Speed – The process I described above (laser cutting, putting the tubes in jigs, welding) takes a ton of time, which means a much more limited production and therefore more expense.

Frame Straightness – It’s very difficult to weld the frame so that it’s perfectly straight. Areas have to be built into the frame so that it can be machined so that it tracks perfectly straight, even if the frame is slightly off.

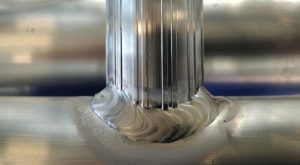

Frame Strength – Welding weakens aluminum. We would have had to either weld 6061-T4 aluminum and then after welding, heat treat it to 6061-T6 to recover the annealing/weakening the welding did… Or, we would have welded 6061-T6 and lived with the weakening the welding does to the metal directly adjacent to the weld. And since we are deathly allergic to cutting corners, this wasn’t going to work.

Frame Weight – It’s very simple, the welded frames were heavier than the frames cut from aluminum plate and bolted together.

Frame Repairability – With the frame bolted together, if any part of the frame is damaged, you unbolt it and try to straighten or repair it as needed. If you can’t fix it, we can send you a replacement piece. You will only need allen wrenches and a few sockets to take the whole thing apart. This is obviously not true of a welded frame.

Flexibility of Manufacturing – All of the descriptions above should make it clear that making a welded frame locks in a lot of decisions and systems. For example, it’s difficult, time consuming, and expensive to adjust welding jigs. But with the CNC router system, if—for example—we wanted to try making a shorter or longer ADV1, all we have to do is change the CAD design, upload the new design to the router, and it’d cut out the new pieces. Assemble them, and off we go!

The Solution Was Clear

With all of these facts stacked on one side of the equation, the solution to how to design and construct the ADV1 was very clear. The only issue…we have to buy a lot of bolts! We will deal with that just fine!

We hope you can come by one of the events we’re attending this summer and check it out in person!